Quá trình sấy bùn

Hồi sinh, Đổi mới, Nâng: Làm cho sự khô chính xác xuất sắc thông qua quá trình sấy bùn!

Thông tin nào về quá trình sấy bùn mà bạn nên biết?

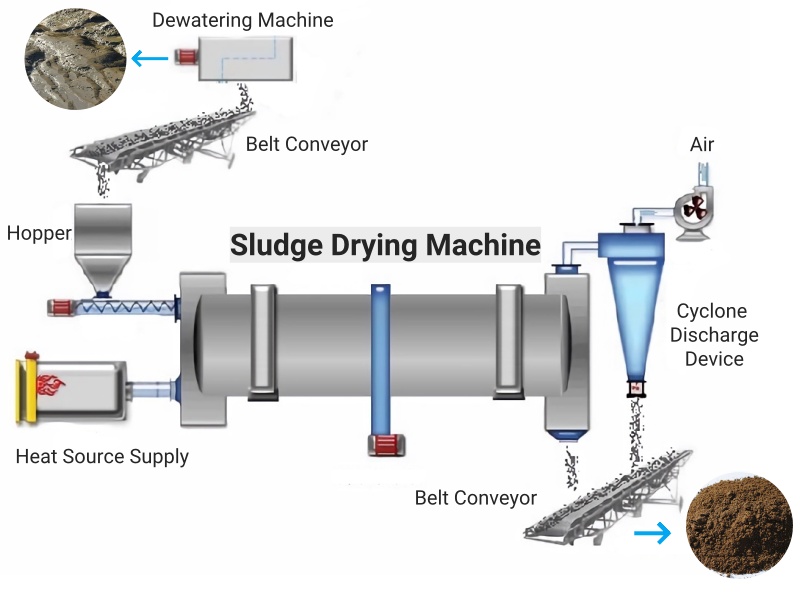

Việc làm khô bùn trong quản lý có thể được chia thành hai bước chính: tách bùn và sấy khô.

Phần 1: Tách bùn hiệu quả

Nói chung, bùn thải thường chứa độ ẩm cao, ở trong 80-90%. Tại thời điểm này, Để tăng cường hiệu quả sấy, bạn tốt hơn để điều trị khử nước. Do đó, Bạn có thể chọn Máy làm mất đi độ nghiêng hoặc Máy khử nước báo chí.

Phần 2: Quá trình sấy bùn

Quá trình này nhằm mục đích làm bay hơi nước trong bùn để giảm khối lượng và trọng lượng của nó. Tiêu biểu, Chúng tôi thường áp dụng không khí nóng hoặc các kỹ thuật sưởi ấm khác để phơi bùn vào môi trường nhiệt độ cao. Ngoài ra, Máy sấy trống quay là một lựa chọn tuyệt vời.

Quá trình sấy bùn là gì?

Máy sấy bùn là một thiết bị hiệu quả được thiết kế để xử lý bùn ướt bằng cách làm bay hơi nhanh thì độ ẩm của nó. Việc phân định rõ ràng các khu vực làm việc và độ chính xác trong thành phần thiết bị làm cho máy sấy bùn trở thành một người biểu diễn nổi bật trong các ứng dụng thực tế của ngành chế biến bùn. Chọn máy khử nước và sấy của chúng tôi để xử lý bùn hiệu quả và đáng tin cậy!