What Factors will Affect the Price of a Rotary Dryer

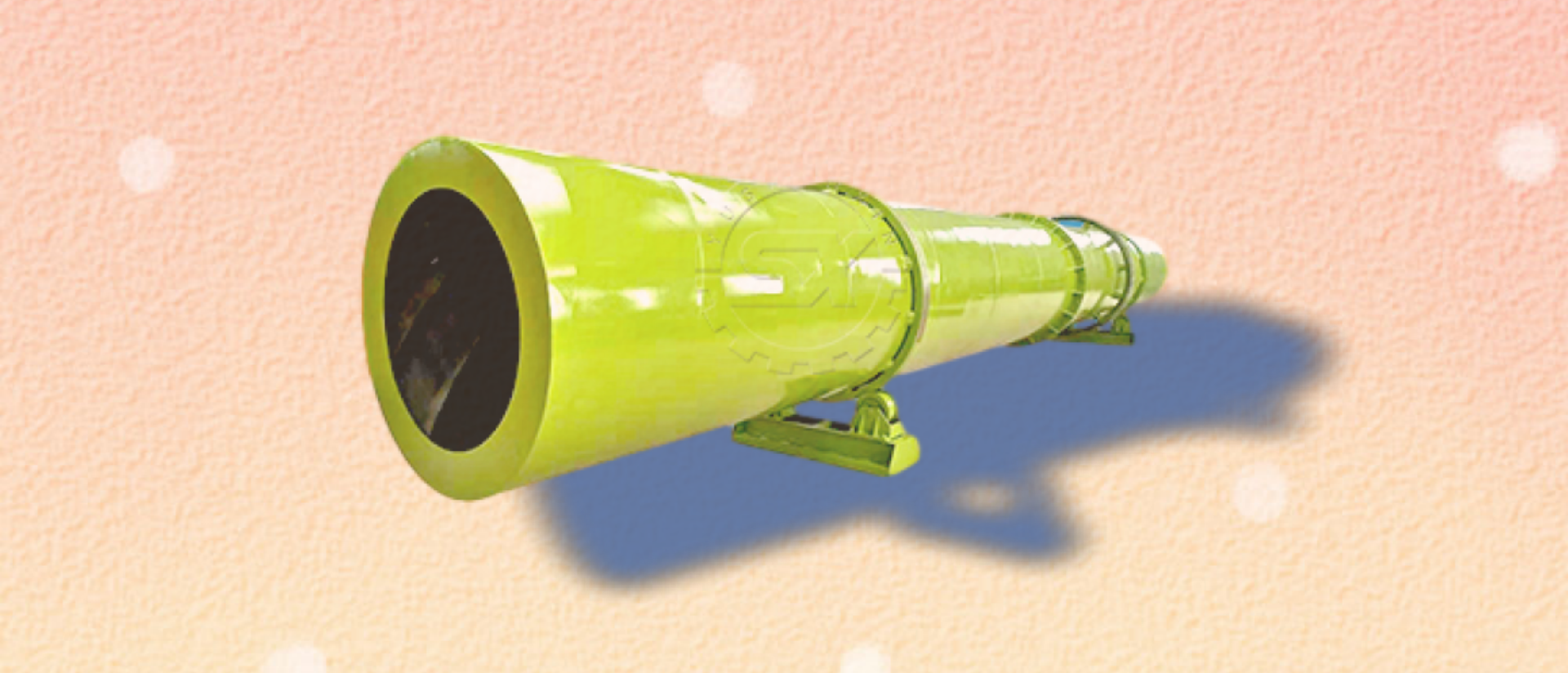

The price of rotary dryers is probably one of the most concerned problems of customers. Actually, there are many factors can affect the price of a rotary drum dryer, chẳng hạn như năng lực, vật liệu, thiết kế và như vậy. There is no doubt that different configurations have different prices. The following is a detailed introduction for the different configurations.

- Materials

The shell of rotary drying machine can be made of a variety of materials.

Precise Design

Some parts of the dryer need to be carefully designed to make the dryer not only improve the work efficiency and save energy.

The burner is the engine behind the dryer that determines the watt output. Burners can be designed for use with a variety of fuel sources, including natural gas, than, oil, vân vân. Choosing the right burner size is crucial to drying materials correctly and efficiently.

Where the combustion chamber and discharge breech meet the drum, seals are needed to connect the fixed parts to the rotating drum. The aim is to prevent air and material from leaving the drum prematurely. Again, many different sealing options exist depending on the needs of the material to be handled.

- Dung tích & Price of Rotary Dryer

We have nine types of rotary dryers with different outputs. And we will introduce them to you according to the output from small to large. And we can design different models, size and length accorrding to customer’s requirements. Nói chung, the same model of different lengths of the dryer price is not the same, while the longer the price will be slightly higher.

Trường hợp

We have a customer in the UK who is looking for a chicken manure dryer to dry about 4,000 tonnes of wet chicken manure per year. The fertilizer has a 70% water content, it needs to dried to 15% water content, and then make the dried fertilizer into pellets.

This is because the moisture content of chicken manure is too high. Firstly I will equip the customer with a dehydrator, and then dehydrate the chicken manure containing 70% moisture into about 50% Độ ẩm.

Thứ hai, use the dryer to dry the chicken manure containing about 50% moisture to contain about 15 % chicken manure. As the customer’s requirement is the annual output of 4000 tấn, the output of dryer per hour is about 1.4 tons if it is calculated by working 280 days a year and 10 hours a day. Vì thế, customers should choose the smallest size dryer. That is enough. As mentioned above, the quotation of the smallest dryers is $3,000 ĐẾN $4,000.

Cuối cùng, the customer also needs to dry the chicken manure for granulation. Vì thế, the customer also needs a flat die granulator. You might wonder that why is it a flat die granulator? Because when using the flat die granulator, the moisture of raw materials should be between 10% Và 15%, and the dried chicken manure just meets this granulation condition.

Dây chuyền sản xuất

Taking chicken manure organic fertilizer production line as an example. Chicken manure organic fertilizer production line is based on chicken manure as raw material. Through a full set of fertilizer production system processing, configuration scheme can be based on the production demand of customers to select.

The production process of chicken manure organic fertilizer is closely related to the equipment configuration of organic fertilizer production line. The complete equipment of general organic fertilizer production line mainly includes fermentation system, hệ thống sấy, deodorization and dust removal system, Hệ thống nghiền nát, hệ thống đợt, Hệ thống trộn, Hệ thống tạo hạt, screening system Và finished product packaging system.

Chicken manure organic fertilizer production process is as follows. Organic fertilizer raw materials such as animal manure after fermentation into the semi-wet material grinder for grinding. And then you may add nitrogen, phosphorus, potassium and other elements to make the mineral elements to meet the required standards. After stirring with a blender, you can make them enter the granulator to make pellets, and then dry with a dryer. Through the screening machine screening, qualified products directly with packaging machine packaging, unqualified products returned to the granulator for granulation.