Sludge Drying Equipment

In urban development and industrial activities, it’s quite frequent to discharge a large amount of wastewater. At this moment, it occurs heavy sediment, namely sludge. Most chemical factories and water purification plants are concerned about how to address this issue. As a result, our company designs a specialist drying equipment — sludge drying equipment. It is developed and constructed specifically for materials with high moisture, high viscosity, and low calorific value.

+8618203993035

info@fertilizerdryer.com

What Industries Or Wastewater Treatment Processes Benefit The MostFrom The Application of Sludge Drying Equipment?

The mud dryer is commonly be of use to dry activated sludge, sewage sludge, petrochemical sludge, paper sludge, printing and dyeing sludge, tannery sludge, electroplating sludge, municipal sludge, bio-fermentation bacterial waste, distillating dregs and other high humidity materials. General speaking, these materials have the characteristics of high moisture, high viscosity, and low calorific value.

Why is this dryer suitable for industrial sludge drying? Because rotary sludge dryer can dry high moisture materials with an initial moisture content about 85% at one time to the final moisture of less than 12%. Besides, sludge drying time is short, usually 2-10 minutes, and the sewage sludge drying temperature can reach 700℃, so it suits for commercial production on a large scale. After slurry dehydration and drying, the moisture content and the volume is reduced, so are the transportation costs.

How About The Sludge Drying Market Size?

The finished products of the dry sludge has flexible applications, depending on the drying technique and the properties of the dried materials. Here are some sales channels to expand your business.

Agricultural Applicability

The sludge treated by sludge dryers is rich in organic matter and nutrients, and can serve as the soil conditioner. Because it can improve soil structure, increase soil water retention and permeability, and provide the nutrients required by plants.

Biofuel Production

Some types of sludge products can be used as biomass fuel. These sludge after the drying process can be burned to generate energy, such as for heating or power generation. And as a renewable resource, it has little pollution and low energy consumption.

Engineering Materials

For one thing, you can add certain types of sludge products to building materials, such as bricks or concrete, to enhance their strength and durability. For another thing, you can make dry sludge as filler materials, such as filling soil or landfills in civil engineering.

Fertilizer Production

You can reprocess sludge after the drying disposal with the organic fertilizer production equipment to transfer into fertilizer. Its organic matter and nutrient composition have a positive impact on soil fertility. You can contact us for more production projects.

Where to Buy The Sludge drying Equipment?

Zhengzhou Shunxin Engineering Equipment Co., Ltd is a leading hi-tech enterprise. In addition, we are engaged in producing drying equipment, integrating product research and development, manufacturing, and sales. Furthermore, our company continuously introduces advanced foreign technology and independent research and development, and has formed special product characteristics. As a professional manufacturer of drying equipment and drying projects, we welcome inquiries from domestic and foreign customers, and give comfortable sludge drying service experience.

Shunxin Machinery

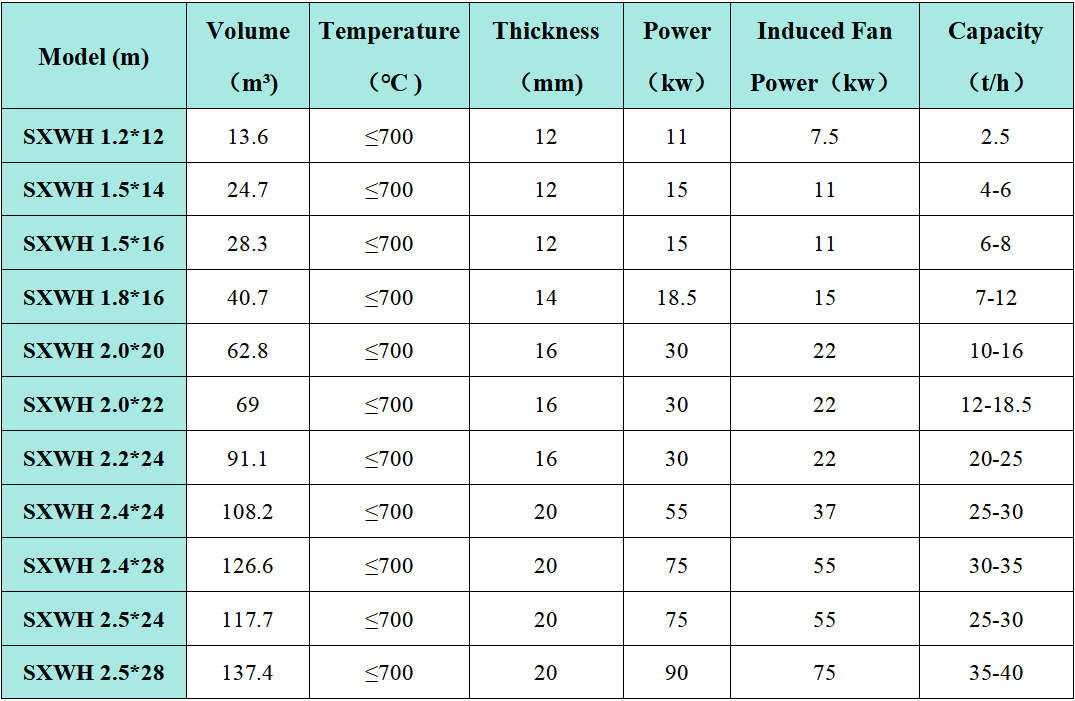

Parameters of Sludge Dryer

How does a sludge dryer work?

Sludge drying facility mainly contains the screw conveyor, induced draft fan, the feeding machine, heating source equipment, the rotating cylinder, the dispersion device, the discharge machine, deodorant equipment and the electric cabinet.

Firstly, you can employ a loader type feeder or the mobile belt conveyor to transport the wet sludge to the dryer. And the rotating plates on the internal drum wall make high humidity materials up and down.

The Lifting Blades of Rotary Drum Dryer

Secondly, while falling, the crushing device breaks the sludge, and hot air passes through the materials’ surface for heat and mass transfer. The cleaning device cleans sludge adhering to the wall of the lifting plate.

Thirdly, by the repeatedly rotating action, the bulk material continuously increases the surface area to be exposed to hot air and dried until they are broken into small particles. Then these particles are discharged from the outlet while reaching their perfect moisture content.

Dust Removal Equipment For Drying Post-treatment

The fine powder entrained by hot air is collected by the dust collector. At the same time, the high-temperature exhaust gas is purified and deodorized by deodorization equipment before emission.

Why to Choose SX Drying Machinery?Stable Sludge Drying Performance

And beyond that, we also provide heat pump sludge dryer, electric sludge dryer, low temperature sludge dryer, thermal sludge dryer and many optional models of sludge drying equipment for your needs! We have stock supply. If you need it, please contact us in a timely manner and we will ship it to you as soon as possible.