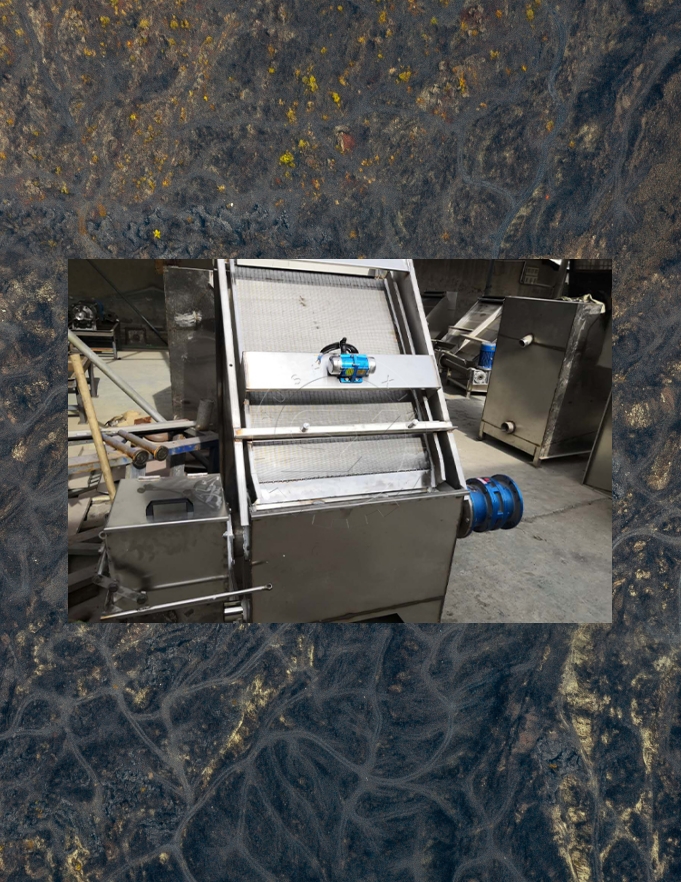

Inclined Dewatering Machine for Sale

As a solid-liquid separation machine, inclined dewatering machine for sale can efficiently handle the discharged manure or sludge from livestock and poultry farms.

Which Materials Can Use in The Inclined Dewatering Machine?

Our inclined solid-liquid separator is a small-scale machine for organic wastes with high water content and low solid content.

One thing is for sure — this machine is tiny in size, about 3-6 square meters. Besides, we specifically design for the aim of the fine impurities’ separation. Obviously, it is appropriate for the finial treatment or filtration of agricultural sewage treatment, as well as for the material pre-treatment in small organic fertilizer plants.

There is a certain difference in the processing speed of organic solid materials according to the material viscosity and humidity. Hence, the production capacity varies according to the actual situation in different places or weather.

For example, in a general way, you can use the SXTSX-800 to process 20-25 m³ of cow dung per hour; 10-15 m³ of chicken manure; 20-25 m³ of pig manure; 20-25 m³ of digestate; 15-20 m³ of wine lees; 10-15 m³ of traditional Chinese medicine dregs; 10-15 m³ of other dregs.

- Other Wide Applications of Inclined Dehydrator

Firstly, you can use this type dewatering machine to remove suspended solids, floating matter, sediment, and other solid substances in paper making, slaughtering, leather, sugar, brewing, food processing, textile, printing and dyeing, petrochemical, and other small-scale industrial factories for wastewater treatment.

Secondly, the inclined dewatering equipment can recover fibers, dregs, and other useful substances in paper making, alcohol, starch or food processing, and other industries.

Thirdly, it also can be of use in processing sludge or river dredging.

Fourth, solid-liquid separation is a essential process in the manufacturing of organic fertilizer. Moreover, after separation, you may immediately pack and transport the manure residue to apply directly or continue making fertilizer.

Where to Buy High-quality Inclined Dewatering Machine for Sale?

If you are looking for the dewatering machine for your organic fertilizer production plants, you can completely consider our company. Let us introduce ourselves as a leading firm with rich production experience in producing the fertilizer dewatering equipment.

Our inclined dewatering machine fully consists of the motor, the reducer, the mixing device, the transfer pump, pipeline, pipe strap and electric cabinet.

To be honest, our equipment has strong structure and stable performance. This is because:

How Does A Inclined Dewatering Machine Work?

The reason why this manure solid-liquid separator is called inclined dewatering machine is that the main body is a stainless steel filtering screen surface with precise steel rods in the wedge shape. Moreover, it is of installation on the frame at an angle of 45°, with the motor on the top of the filtering screen, and the extrusion screw on the bottom.

- Work Principle

A water pump lifts the mixing sewage and residues to the liquid storage box of the solid-liquid separator.

The manure wastewater spreads uniformly onto the inclined screen surface through the overflow-weir liquid distributor.

This step efficiently ensures the solid substance remained while preventing the screen surface from becoming clogged.

Meanwhile, the vibration motor push the solid materials to the spiral shaft in the screen. And after extrusion and separation, there are solid emissions from the bottom, achieving the objective of solid-liquid separation.

This states that the primary dewatering operation is still extrusion, such as the working principle of the ordinary pig manure dewatering machines. Through the filtration of the inclined screen surface, this machine can easily recover all kinds of solid or colloidal substances.

As a result, it effectively reduces the burden of the following extrusion process and improves the efficiency. Therefore, in terms of use effect, it is a good choice to use inclined solid-liquid separation dehydrator for material disposal with more than 75% moisture.

TOP 1

First of all, our plant, Shunxin, can customize the filtering screen specifications according to the needs of customer’s materials, and even we can design its density for gradual separation.

TOP 2

Secondly, the whole machine is made of 304 stainless steel, with wear resistance and corrosion resistance. And full stainless steel shell makes the equipment more durable than carbon steel or ductile iron.

TOP 3

Thirdly, our inclined dewatering machine for sale has complete functions. Also, the whole machine combines the pumping system, vibration system, extrusion system and automatic washing system, which improves the sewage treatment capacity and effect, as well as the recycling of animal manure.

By use effect of customers and many years of continuous investigation, we create inclined dewatering machine with greater performance. As an organic fertilizer equipment, it has a small occupation of land, simple operation, and easy maintenance. Furthermore, its stainless steel design and a portable cleaning system fulfill the demands of liquid and viscous manure processing.

We are consolidating current goods on the basis of continuous product development, so that our products have great progression in the specifications and variations to satisfy the demands of various customers. Welcome all clients to send email for quotation or call from business operations. Our prices do not include transportation expenses due to different distance by regional logistics. Shunxin let customers worry-free shopping!