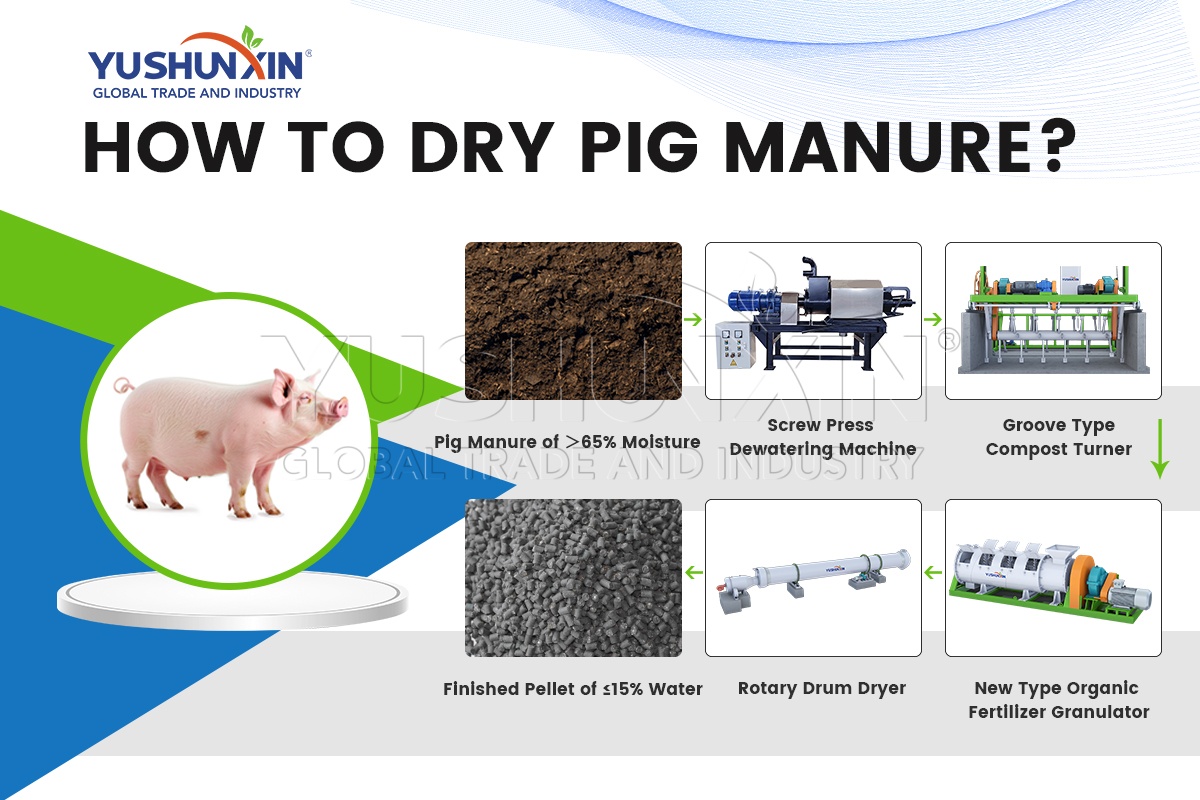

What Are 4 Phases to Reduce Moisture Content of Pig Dung?

Naturally, the process of reducing moisture content in swine dung involves four key phases, each crucial for effective organic fertilizer production.

Naturally, the process of reducing moisture content in swine dung involves four key phases, each crucial for effective organic fertilizer production.

How to Dewatering Pig Manure to 60-65% for Organic Fertilizer Pre-treatment?

If you are seeking efficient dewatering solutions for processing pig manure, our company offers two cost-effective solid-liquid separators. They can reduce moisture content effectively down to 60-65% level. Moreover, there are flexible moisture reduction options with varying degrees of their dehydration ability. One is screw press dewatering machine, with stronger dehydration effect, making it ideal for preparing manure for most organic applications. Another is inclined dehydrator, suitable for water soaked swine feces disposal.

If you are seeking efficient dewatering solutions for processing pig manure, our company offers two cost-effective solid-liquid separators. They can reduce moisture content effectively down to 60-65% level. Moreover, there are flexible moisture reduction options with varying degrees of their dehydration ability. One is screw press dewatering machine, with stronger dehydration effect, making it ideal for preparing manure for most organic applications. Another is inclined dehydrator, suitable for water soaked swine feces disposal.

1

Inclined Dewatering Machine

2

Screw Press Dehydrator

1

Inclined Dewatering Machine for Pig Manure Dehydration to 70% Water Content

Honestly, if you want to dispose fresh pig dung with more water content of 85%. At this time, we advise you to buy our inclined dewatering machine. Indeed, the solid-liquid separation rate is up to 80%, while you can remove part of water in pig dung. Our factory have 2 models of inclined solid-liquid separator. Also, it can handle pig waste maximum of 40m³/h. And the discharged pig manure solids after mechanical dehydration contain at most 70% moisture. Furthermore, the screen mesh and whole shell of inclined dewatering machinery adopt 304 stainless steel, and the components all apply precisely nickel alloy. Therefore, it has high corrosion resistance so than you don’t have to worry damaging this machine by dehydrating high humidity pig manure.

2

Screw Press Dewatering Machine for Pig Manure Dehydration to 60% Water Content

If you want to further process pig manure, you may consider purchasing a spiral extrusion dewatering machine. Moreover, we have two models, both of which occupy a small area of 1-3 square meters. It can dehydrate pig dung down to 60% at a time. Our equipment can automate the processing of pig manure. Through the pump, swine manure is sent to the feed inlet of the dehydrator. Under the squeezing by spiral blades, the wastewater flows through pipelines. And the residue after dewatering is transported to the next step by a conveyor belt. Thus, screw extrusion dehydrator can be widely used in the dehydration operation of high humidity residue materials before drying, successfully solving the problem of dehydration of high viscosity materials in many industries.

3

Screw Press Dewatering Machine for Pig Manure Dehydration to 60% Water Content

Why to Dry Swine Manure for Organic Fertilizer Production?

The moisture level of swine manure affects its treatment and usage significantly.

- Firstly, excessive moisture content raises the volume and weight of swine dung, which influences transportation and storage costs. At the same time, pig excrement with a high water content is more prone to pollute the environment.

- Secondly, the high water content makes decomposing the organic matter in pig dung more difficult.

As a result, before utilizing swine dung to manufacture organic fertilizer, you must primarily reduce its water content.

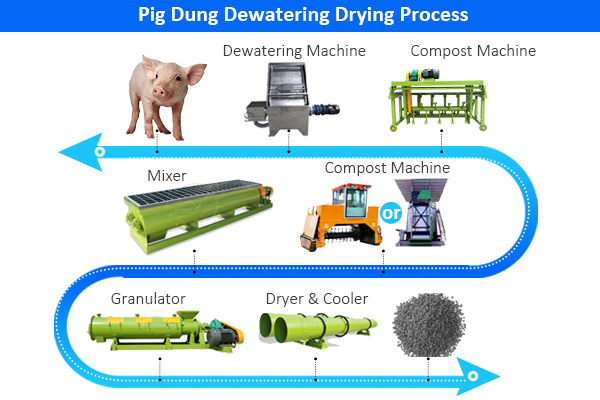

Ⅰ. Dewatering Pre-treatment of Swine Dung

For animal manure like pig dung, its moisture is always higher than 70%. At this time, we advise you to buy our inclined dewatering machine for mechanical dehydration. That is to say, it reduces water by pressing, sedimentation, filtration, centrifugal separation, etc. This method can only remove part of free water in manure, and the bound water still remains.

For instance, a farm with 3,000 pigs installs a pig dung dewatering machine. According to calculation, a pig produces 2.5kg of dung one day, so the farm totally generates 7.5 tons of dilute pig manure a day. By the dewatering machine, this farm may get approximately 3 tons of pig manure with about 50% moisture content.

How to Use Pig Manure Inclined Dewatering Machine?

- 1

The pump lifts the swine dung to the liquid storage box of the inclined solid-liquid separator.

- 2

Pig manure wastewater spreads uniformly onto the inclined screen surface through the overflow-weir liquid distributor.

- 3

Under the action of gravity and vibration, the filtered water flows out from the screen surface’s gap to the storage box and discharges through the drainpipe.

- 4

The vibration motor pushesthe pig dung to the spiral shaft in the screen. And after extrusion and separation, they are discharged from the bottom.

Ⅱ. Composting & Fermentation of Pig Manure

The water content of swine dung remains relatively high after mechanical dewatering, often 40-60%. Composting is a typical method of turning pig excrement into organic fertilizer by adding the appropriate amount of microbial agents for fermentation. Then, you can lower the water content after composting to 30–50%, which is more suitable for organic fertilizer granulation.

Here, it should be noted that if the moisture content of pig dung after composting is too high, you may need to dry again to meet transportation and storage requirements. Meanwhile, if it occurs environmental problems such as odors, it is necessary to do further deodorization treatment.

3 Tips for Pig Manure Moisture Removal During Composting Process

During the composting process, you can absorb and neutralize moisture by adding absorbent auxiliary materials (e.g. wood chips, straw, etc.). It is also important to turn the manure regularly during this process to increase the oxygen content and promote microbial decomposition, as well as to facilitate the evaporation and dissipation of water.

In the fermentation pot, you can apply the secondary fermentation technology. In a word, you can carry out aerobic fermentation in advance, and then do anaerobic fermentation, which can remove moisture and odors better.

The fermentation equipment produced by our company covers less space and no pollution (sealed fermentation). And you can control automatically aeration, temperature, agitation and deodorization.

Processing pig manure with composting equipment is also an effective method. You can remove moisture through this iterative process of aeration, oxygen supplementation, warming and cooling.

Our company provide 3 kinds of rail type compost turner and 2 kind of windows type compost turner for your options. These equipment can accurately regulate moisture through automatic controlling and adjustments, while minimizing the amount of manual labor and time costs.

Ⅲ. Granulation & Drying of Swine Excrement

After fermentation and maturation, the pig manure’s moisture content achieves 20–40%. In the organic fertilizer production line, after crushing and mixing process, you can make pellets after crushing and mixing process. Nevertheless, the moisture content of the semi-finished particles is still high, so most of the cases we recommend to use our rotary drum dryer for drying. After the drying and cooling process, the moisture content of the particles reaches the marketing standard, less than 10%.

3 Tips for Pig Manure Moisture Removal During Granulation Process

Single Shaft Mixer Used in the Fertilizer Blending Process in Granulation Plant

According to the local soil structure, you can mix pig dung with appropriate amounts of nitrogen, phosphorus and potassium elements. Meanwhile, you can also add other additives, such as humic acid, which can improve the fertility and adaptability of the manure.

Our horizontal mixer has many models for customer’s actual production needs, which includes adjusting mixing time, speed, and capacity based on the scale of the pig dung drying operation. For example, SXWJ-1630 has the output of 10-15 t/h, the rotating speed of 21 r/min and its power is 22 kw.

New Type Organic Fertilizer Granulator

You can use the organic fertilizer granulators to make pellets. We have four types for disposing pig dung. Among them, the new type organic fertilizer granulator is well received by customers.

It is necessary to pay attention to the control of water during this process. Too much water may lead to uneven granulation or soft particles, while too little water may lead to hard particles or impossible to granulate at all.

Dryer for Fertilizer Production

More significantly, you can purchase the fertilizer drum dryer to further remove the moisture in the semi-finished particles to meet the standard requirements. In addition, the rotary drum design is to reduce the drying time about 10 minutes and moiture to less than 12% once.

The drying process needs to pay attention to the control of temperature and humidity in order to avoid the impact on product quality. You may need to select relevant induced draft fan, heat supply equipment, fertilizer cooling machine, etc. to use.

In conclusion, in the organic fertilizer production process, there are three methods for the water removal.

- Firstly, you can remove high water content of pig manure by dewatering machine.

- Secondly, you can use the compost fermentation equipment to make water content meet granulation requirements.

- Finally, you must use the dryer to reduce moisture to meet the marketing standard.

Please contact us for more details!