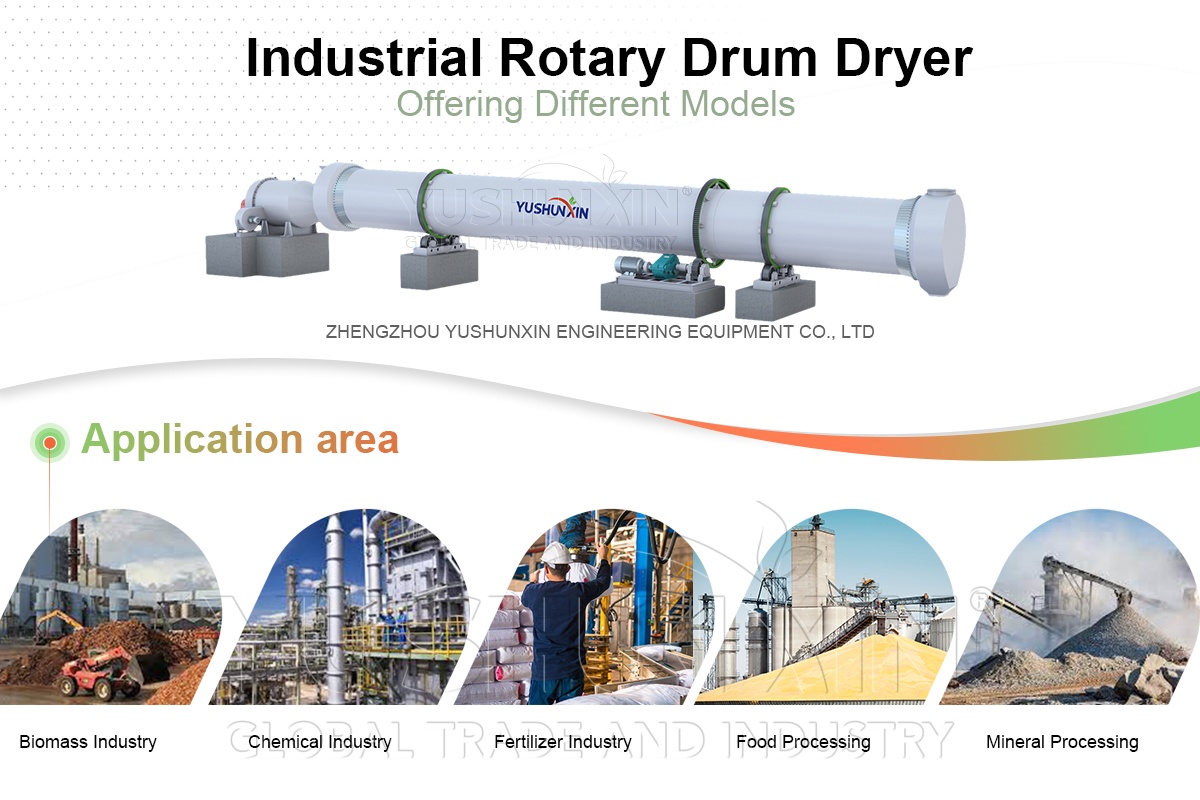

What Is The Applications of A Necessary Drum Dryer Machine?

Rotary dryer, an industrial dryer, is extensively of use to dry different materials from many businesses, like slurries, powder, granules, flakes and solids. Moreover, it can address the need for an efficient and reliable method of material moisture removal.

What Are The Main Components of The Drum Dryer Machine?

All of our dryers are custom designed to meet the unique processing needs of your material. Whether you need low or high inlet temperatures, short or long residence times, countercurrent or cocurrent, our design team can design a drum drier for your application. While a rotary drum dryer machine is custom-designed based on the material to be processed, its construction is standard to some extend and generally customized in terms of size, materials, mechanical components and add-ons.

How Does A Drum Dryer Machine Work?

- The belt conveyor sends wet materials to the hopper, and enters the drum from the feeding port. The main body of the rotary drum drying equipment is a slightly inclined rotatable cylinder.

- After the material enters the cylinder, it directly or upstream contact with the hot air passing through the cylinder, or in effective contact with the heating wall.

- After drying, the lower part of the other end discharges the products. During the drying process, the material is dried in the drum. The barrel rotates slowly, moving from the higher end to the lower end under the force of gravity.

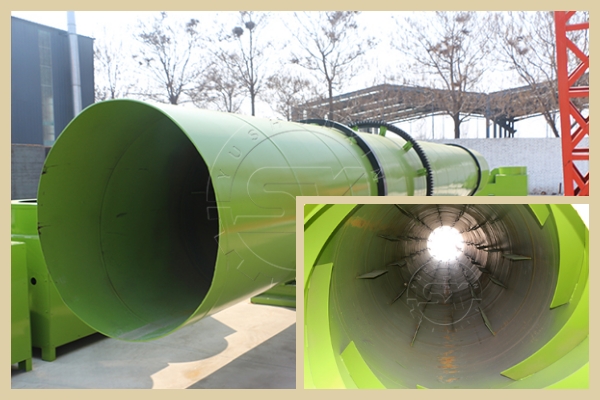

- The inner wall of barrel is equipped with plates, which can pick up and scatter the materials continuously, which greatly increases thermal contact surface of materials, improves drying speed and accelerates materials forward movement.

- After the heat carrier dries the material, the cyclone dust collector collects the entrained dust and then empties.

- Combined with hot air, these rugged industrial dryers use tumbling action to efficiently dry materials.

- In most cases, rotary drum dryers directly fire, which means that the hot air is in direct contact with the material.

- However, some dryers are indirect, that means the dryer heats materials from the outside to avoid direct contact of the material with the hot air.

- The hot gas flow can flow from the feed end to the discharge end, or from the discharge end to the feed end.

- The direction of the airflow and the inclination of the drum determines the speed of the material moves through the dryer.

What Are The Characteristics of The Drum Dryer Machine?

- The drum dryer is the most reasonable equipment for simultaneous evaporation and drying. Besides, you can carry out its operation continuously, so the product quality is stable.

- The drying time is short. Hence, you shouldn’t keep the material exposing to high temperature for a long time, so that heat-sensitive materials also have good drying effects.

- Since the drum dryer is a heat transfer drying system, its thermal efficiency is superior to other types of dryers, it is very economical.

- The drum dryer machine is flexible in operation and suitable for small batch production of multiple pieces. It’s simple to clean and replaces parts easily.