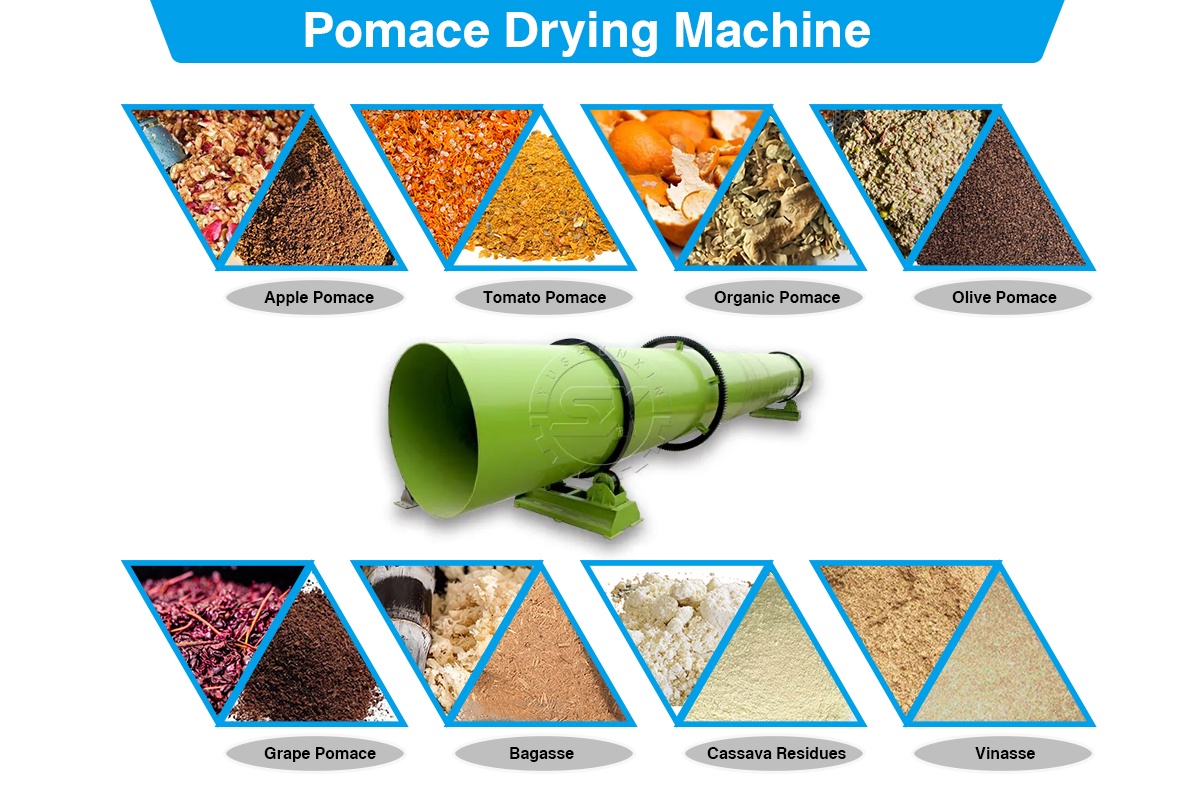

Pomace Drying Machine

What Is The Pomace Drying Machine Price?

In addition, we design different models of fruit pomace drying machines according to their output. And the quantity and size of supporting equipment for each type varies. Thus, only customers specifies their output, material humidity, and requirements can we offer relevant data and a full quotation. In fact, our equipment can make small scale production of at least 0.5-1.5 t/h, so it is very suitable for small fruit plantation to use.

Don’t worry about mass fruit pomace production! Our single piece of drying equipment’s daily processing capacity may exceed 100 tons, with a wide range of applications that can fulfill a variety of large and medium-sized drying projects. Besides, a pomace dryer costs between $6000 and $50,000. Here are three plans for drying fruit waste.

Technical Parameters of Pomace Dryer

| Model (mm) | Inclination (%) | Speed (r/min) | Temperature (℃) | Power (kw) | Capacity (t/h) | Weight (t) |

|---|---|---|---|---|---|---|

| Ф600x6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| Ф800x8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| Ф800x10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| Ф1000x10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| Ф1200x10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| Ф1200x12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| Ф1500x12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| Ф1800x12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| Ф2200x12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| Ф2200x18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| Ф2200x20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| Ф2400x20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| Ф3000x20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

| Ф3000x25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

What Is The Fruit Pomace Drying System?

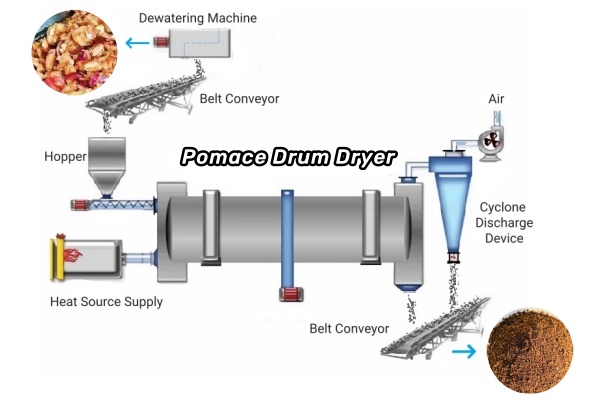

Because fruit residues contain a certain water content, you need to send them to a dehydrator for pre-treatment before entering pomace dryer. At this time, you can have a try at using SX screw press dewatering machine. It can reduce the moisture of fruit waste quickly from 80% to 50%, which can enhance the entire drying efficiency and save the energy consumption.

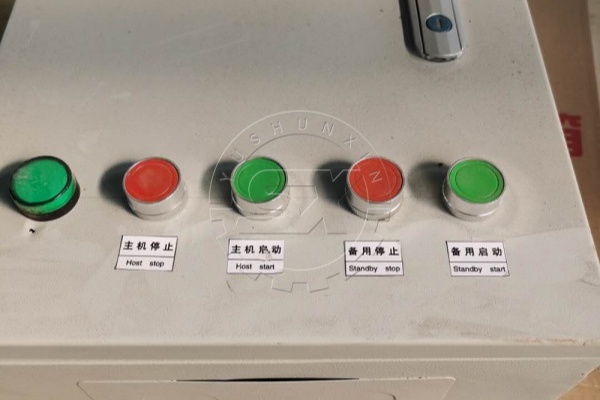

Then, the fruit pomace drying system consists of heat source equipment (hot blast furnace), feeding & discharging devices, rotary drum dryer, induced draft fan, high & low temperature pipelines, dust collection machine and automatic control cabinet.

How Does A Pomace Drying Machine Work?

Where to buy excellent pomace drying processing equipment? We recommend Zhengzhou Shunxin, which has been specializing in the production of drying equipment for 20 years, to minimize material waste and additional cost expenditures for you. As a direct sales manufacturer, our equipment prices are all factory prices, without any middlemen earning price differences, ensuring that you can buy high-quality equipment at a reasonable price. If you have any questions, please contact us for a free quotation.