Sludge Drying Process

Revitalize, Innovate, Elevate: Making Precision Drying Excellence Through Sludge Drying Process!

What Information of Sludge Drying Process You Should Know?

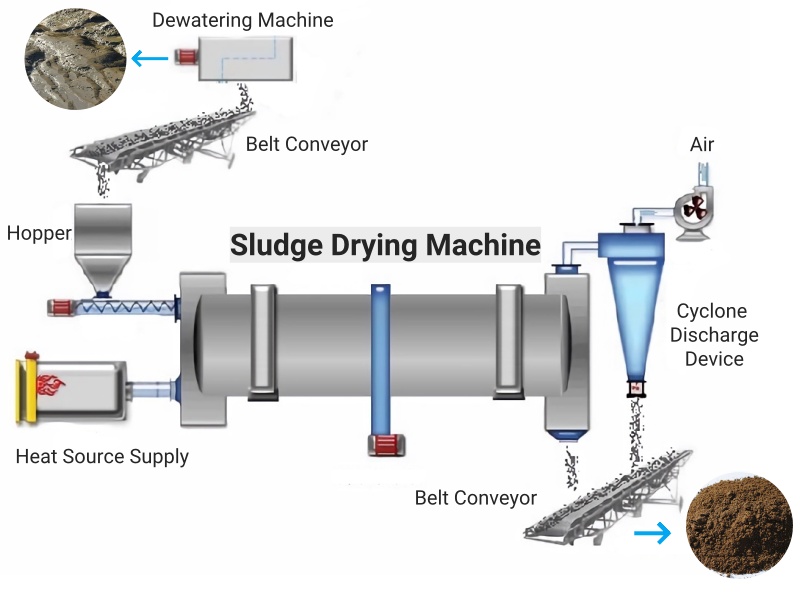

The sludge drying in management can be divided into two main steps: sludge separation and drying.

Part 1: Efficient Sludge Separation

In general, sewage sludge usually contain high moisture content, within 80-90%. At this time, to enhance drying efficiency, you’d better to make dewatering treatment. Thus, you can select our inclined dewateing machine or screw press dewatering machine.

What Is Sludge Drying Process?

Sludge drying machine is an efficient equipment designed to handle wet sludge by rapidly evaporating its moisture content. The clear delineation of working zones and precision in equipment composition make the sludge drying machine a standout performer in practical applications of sludge processing industry. Choose our dewatering and drying machine for effective and reliable sludge treatment!